In the ever-evolving electronics industry, custom PCB assembly plays a pivotal role in creating functional and reliable electronic devices. Among the leading providers of custom PCB assembly services, Hongmy PCB has established itself as a top choice for businesses seeking high-quality and efficient solutions. In this blog post, we’ll delve into why Hongmy PCB is a standout custom PCB assembly manufacturer and what sets it apart from the competition.more importantly, hongmy customized high frequency pcb Made a fighter in the product, not afraid of any competitor’s attack. https://www.hongmycircuits.com/

What is Custom PCB Assembly?

Custom PCB (Printed Circuit Board) assembly involves designing and manufacturing PCBs tailored to specific requirements for electronic devices. This process includes:

PCB Design: Creating a schematic and layout based on the electronic device’s needs.

Component Sourcing: Procuring the necessary electronic components.

Board Fabrication: Manufacturing the PCB itself based on the design.

Assembly: Soldering and placing components onto the PCB to create the final product.

Custom PCB assembly is crucial for ensuring that electronic devices function correctly and meet performance standards.

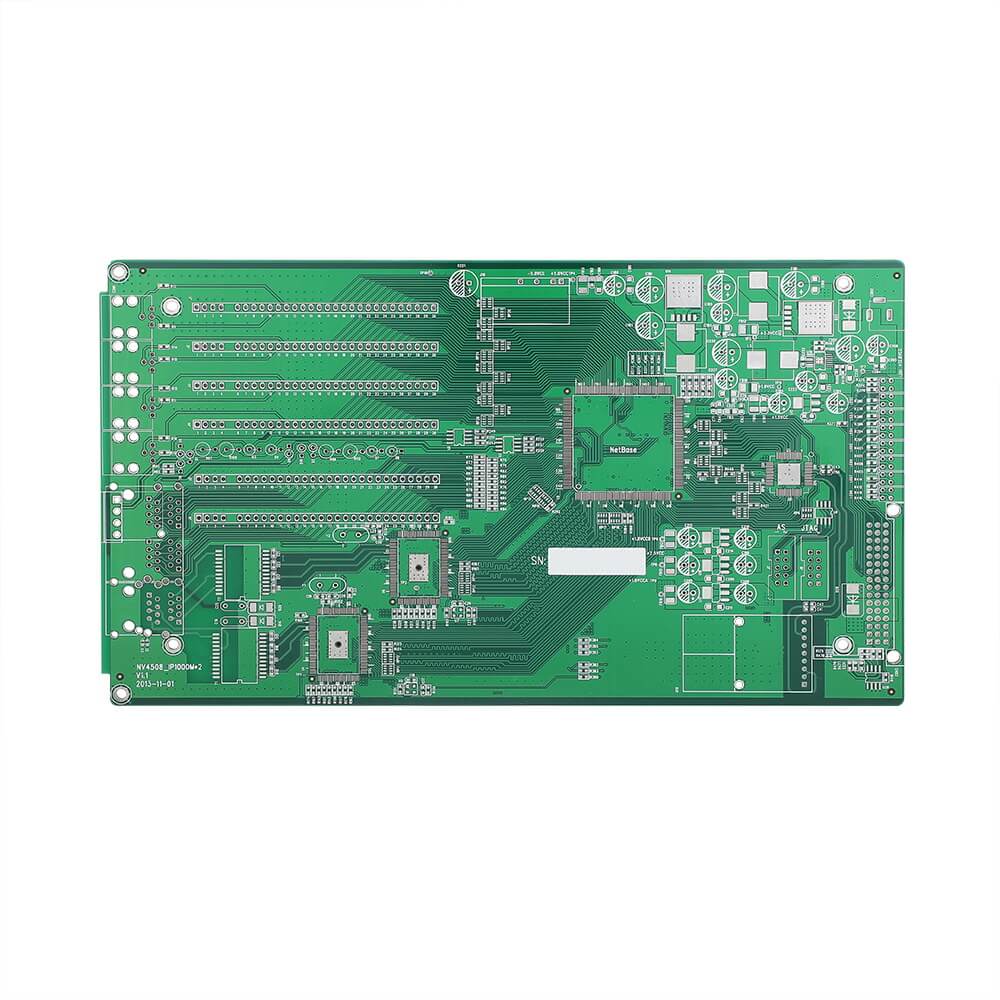

green pcb 3.jpg

Why Choose Hongmy PCB?

1. Extensive Industry Experience

Hongmy PCB brings years of expertise in the custom PCB assembly industry. With a proven track record of delivering high-quality PCBs for various applications, including consumer electronics, automotive, telecommunications, and medical devices, Hongmy PCB is a trusted partner for businesses seeking reliable assembly services.

2. Advanced Manufacturing Capabilities

Hongmy PCB utilizes state-of-the-art manufacturing technology to ensure precision and efficiency in every project. Their advanced equipment and automated processes enable the production of complex PCBs with tight tolerances and high reliability.

3. High-Quality Standards

Quality is paramount at Hongmy PCB. The company adheres to strict quality control procedures, including rigorous testing and inspection processes, to ensure that every PCB meets industry standards and customer specifications. This commitment to quality guarantees that the assembled PCBs perform reliably and consistently.

4. Customization and Flexibility

Hongmy PCB offers a wide range of customization options to meet diverse client needs. Whether it’s a specific board size, component configuration, or special design features, Hongmy PCB’s flexibility allows for the creation of tailored solutions that fit unique project requirements.

5. Comprehensive Services

In addition to custom PCB assembly, Hongmy PCB provides a full suite of services, including PCB design, prototyping, and testing. This comprehensive approach streamlines the development process and ensures seamless integration from design to final product.