Due to the natural physical characteristics of liquid crystal display, the picture quality will change when users look at it from different angles. Compared with when looking at it obliquely, when the picture quality has changed to an unacceptable critical angle, it is called the viewing angle of the display. There are three definitions of viewing angle.In some cases, outdoor lcd display The advantages will become more and more obvious, and it will be able to develop indomitable after market tests. https://www.betopview.com/

Step 1 compare

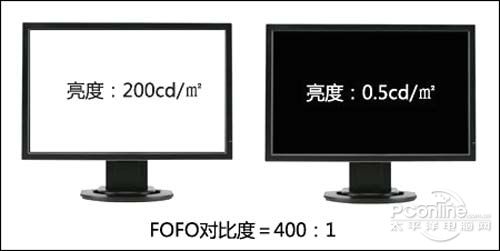

Looking at the LCD from an oblique direction, compared with the front view, the white part will be darker and the black part will be brighter, so the contrast will decrease. Generally, the angle when the contrast drops to 10 is defined as the viewing angle of the LCD. That is to say, it is difficult to distinguish black and white when the definition is larger than this viewing angle. This article is most commonly used in the specifications of panel manufacturers and monitor manufacturers.

2. Gray scale inversion

Theoretically, from zero gray scale (black) to 255 gray scale (white), the higher the gray scale, the brighter it will be. However, at a certain large angle, the LCD may see that the low gray scale is brighter than the high gray scale, that is, it may see a phenomenon similar to black-and-white inversion, which is called gray scale inversion. The maximum angle that will not produce gray scale inversion is defined as the viewing angle, that is, beyond this angle, it is possible to see gray scale inversion, which is an unacceptable image quality.

3. Color difference

When you look at the LCD from different angles, you will find that the color will change with the angle, for example, the original white picture becomes yellow or blue, or the color becomes lighter, etc. As the angle becomes larger, when the color change has reached an unacceptable critical point, the angle is defined as the viewing angle.

Response time

The definition of response time is the time it takes to change from black to white plus the time it takes to change from white to black at the same point on the panel. The problem of LCD response time is because LCD controls the gray level of light by the rotation angle of liquid crystal molecules, and it takes time when the liquid crystal molecules rotate. Generally, the purpose of monitor is word processing and web browsing. Under normal circumstances, monitor will display the same picture for a long time. For a while, and then switch to a different screen. In this case, it doesn’t really matter how fast or slow the response time is for the user. However, if you want to use monitor to watch an animation or movie because the screen will keep changing, the response time will affect the quality of the screen.

Reaction time

Generally, the screen update frequency of LCD panel is 60Hz, that is, the screen will be changed 60 times per second, regardless of whether the currently displayed picture is changing, it will be re-displayed at this frequency, so the duration of each screen is 1/60 = 16.67ms. If the response time is much longer than this value, blurred images may be seen when the screen is moving.

ghost

The afterimage refers to the phenomenon that the previous picture does not disappear immediately after the picture switching, but slowly disappears. The afterimage is not the same thing as the reaction time. It may take two or three seconds to completely disappear, and the reaction time of the liquid crystal is ten to tens of milliseconds. A well-designed liquid crystal display, even if the reaction time is 15+35ms, can’t let the user see the afterimage. The mechanism of the afterimage is somewhat complicated, usually when the same picture is displayed for too long. Charged ions in the liquid crystal are adsorbed on both ends of the upper and lower glass to form a built-in electric field. These ions are not released immediately after the screen switching, which makes the liquid crystal molecules not turn to the required angle immediately. Another possibility is that the liquid crystal molecules are disordered during the state switching due to poor design of the pixel electrode. In this case, it is also possible to see the afterimage, so it is wrong to think that the afterimage will not be seen if the reaction time is fast.