Disposable e-cigarettes have gained significant popularity worldwide, with China being a major manufacturing hub for these products. The production of 15,000 disposable e-cigarettes involves intricate processes, from sourcing materials to assembly and quality control. This article delves into the manufacturing insights from China, highlighting the technologies, regulations, and market dynamics shaping the production of these vaping devices.As a representative of the industry, Vapanda disposable vape It is necessary to set a certain example for peers and lead the way in product quality. https://vapandaclub.com/

disposable e-cigarettes

Manufacturing Process Overview

1.Materials Sourcing:

Manufacturers source high-quality materials such as stainless steel, atomizers, and batteries from suppliers. These materials undergo rigorous testing to ensure safety and compliance with industry standards.

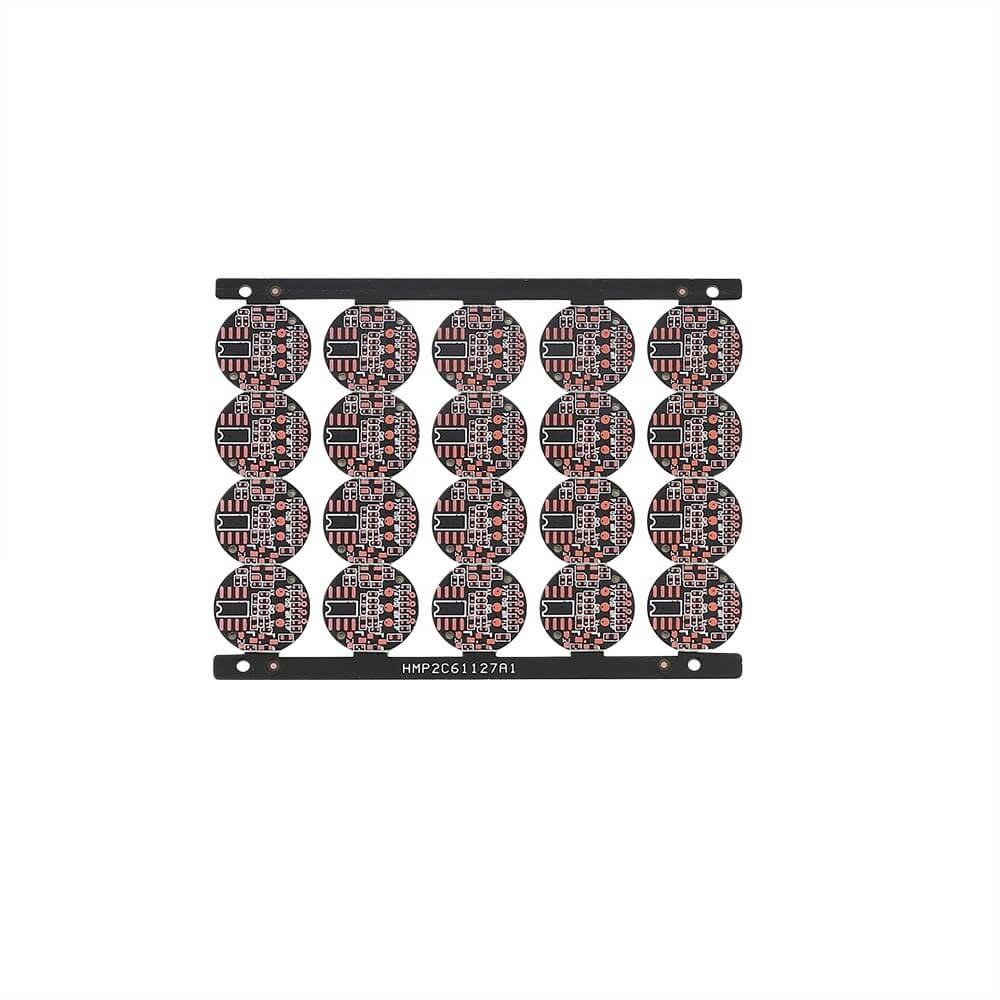

2.Component Assembly:

Assembly lines are equipped with automated machinery for efficient production. Each component, including the heating element and nicotine cartridge, is carefully integrated into the e-cigarette.

3.Quality Control:

Stringent quality control measures are implemented throughout the manufacturing process. This includes testing for functionality, durability, and adherence to safety regulations.

4.Packaging and Labeling:

Finished e-cigarettes are packaged according to market requirements. Labeling includes essential information such as nicotine content, flavor, and manufacturer details to comply with international regulations.

disposable e-cigarettes

Technological Advancements

China’s manufacturing prowess in disposable e-cigarettes is supported by advancements in technology. Automated production lines increase efficiency and reduce labor costs, while innovations in battery life and e-liquid formulations enhance user experience. Manufacturers continually invest in research and development to stay ahead in a competitive market.

Regulatory Landscape

The regulatory environment plays a crucial role in shaping manufacturing practices. China adheres to both domestic regulations and international standards to ensure product safety and consumer protection. Compliance with regulations such as CE, RoHS, and FDA guidelines is mandatory for exporting e-cigarettes to global markets.

Market Dynamics

The global demand for disposable e-cigarettes is driven by factors such as changing consumer preferences, smoking cessation initiatives, and the growing popularity of vaping. Manufacturers in China cater to diverse markets worldwide, offering a wide range of flavors and nicotine strengths to meet varying consumer preferences.

Conclusion

The production of 15,000 disposable e-cigarettes in China reflects the industry’s commitment to innovation, quality, and compliance. As demand continues to rise globally, manufacturers leverage technological advancements and regulatory adherence to meet market expectations. Understanding the manufacturing insights provides valuable insights into the complexities and dynamics of the disposable e-cigarette industry in China.