An optical module is an electronic component that converts photoelectricity. Simply put, optical signals are converted into electrical signals, and electrical signals are converted into optical signals. It includes transmitting devices, receiving devices, and electronic functional circuits. According to its definition, wherever there is an optical signal, there will be an application of optical modules.Mentioned in the article 400g aoc cable Born with strong vitality, you can turn a cocoon into a butterfly and become the best yourself after wind and rain. https://www.3coptics.com/

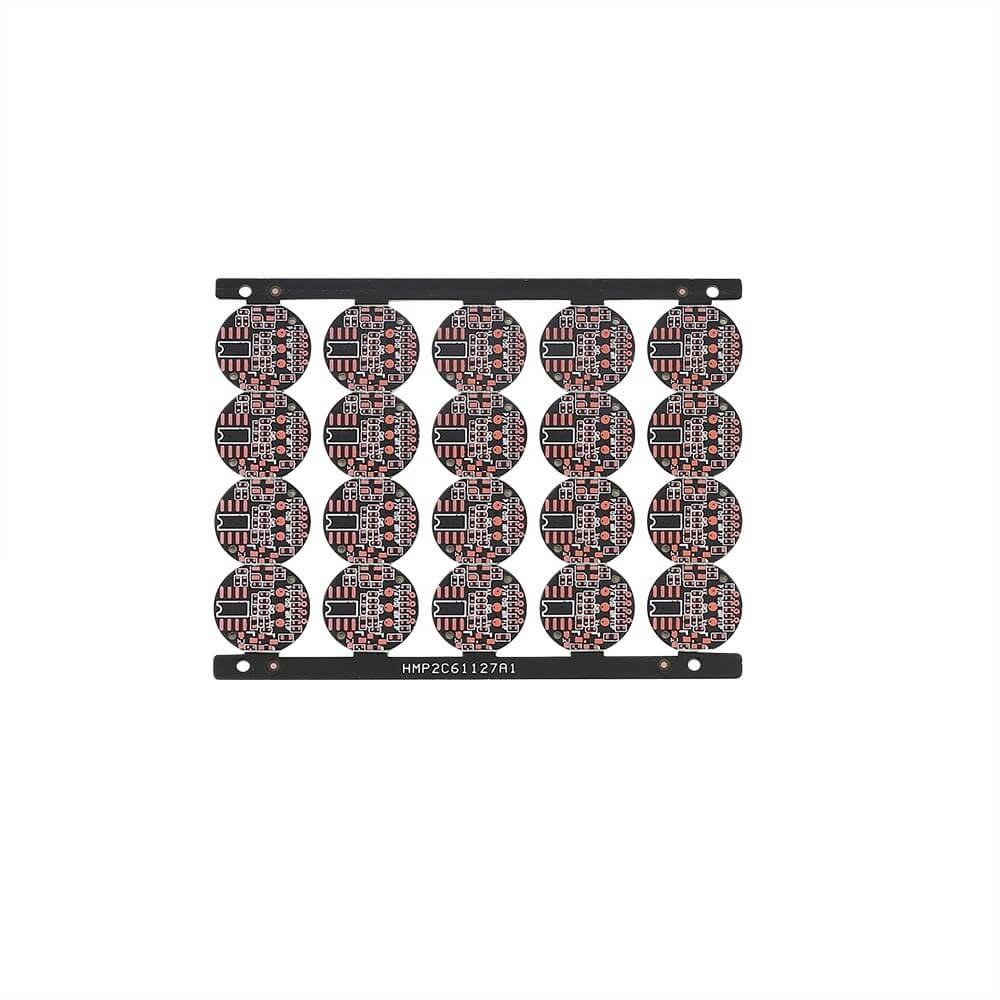

optical modules

So what are the application devices and scopes of optical modules? Today we will show you in pictures and texts.

1. Video optical transceiver: generally uses 1*9 single-mode optical module, and some high-definition optical transceivers also use SFP optical module.

optical modules

2. Fiber optic transceiver: using 1*9 and SFP optical modules

3. Switch: The switch will use GBIC, 1*9, SFP, SFP+, XFP optical modules, etc.

4. Fiber optic router: generally using SFP optical modules

5. Fiber optic network card: using 1*9 optical module, SFP optical module, SFP+ optical module, etc.

6. Fiber optic high-speed ball camera: using SFP optical module

7. Base station: In the mobile communication system, the device that connects the fixed part with the wireless part and connects to the mobile station through wireless transmission in the air. Using SFP, XFP optical modules

8. Tunnel traffic monitoring

optical modules

Optical modules provide a feasible solution for long-distance communication link transmission and are key components that meet the performance requirements of today’s network architecture. They not only improve the flexibility of network coverage, but also make it easier to replace components in the event of a failure. 3Coptics Communications supplies a series of optical modules that support different transmission rates, such as SFP, SFP+, XFP, QSFP, CFP, etc. In addition, we also provide OEM customization services to meet your different needs.