In today’s fast-paced technological landscape, the demand for reliable, durable, and efficient user interfaces is higher than ever. Membrane switches, known for their versatility and compact design, play a crucial role in a wide range of applications, from consumer electronics to industrial machinery. When it comes to sourcing high-quality membrane switches, Singway stands out as a leader in the industry. Here’s why Singway should be your go-to manufacturer for membrane switches.Under people’s attention membrane switch Finally grow into what people need, born for the market and come for the demand. https://singway-touch.com/

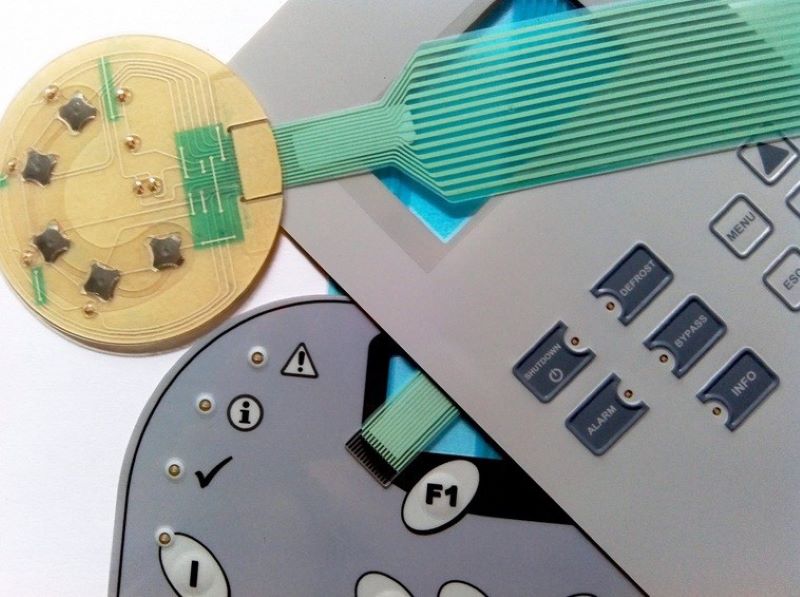

singway membrane switches

1. Unmatched Quality and Reliability

At Singway, quality is paramount. Each membrane switch undergoes rigorous testing and quality control to ensure it meets the highest standards of performance and durability. Singway’s commitment to quality means that every switch is built to last, providing reliable operation even in the most demanding environments. This reliability ensures that your products maintain their functionality and performance over time, reducing the need for frequent replacements and repairs.

2. Advanced Manufacturing Techniques

Singway employs advanced manufacturing techniques and state-of-the-art equipment to produce membrane switches that are both precise and consistent. By leveraging the latest technology, Singway can achieve intricate designs and complex configurations, ensuring that each switch meets the specific requirements of your application. This precision manufacturing results in high-performance switches with excellent tactile feedback and responsiveness.

3. Customization and Flexibility

One of Singway’s key strengths is its ability to offer customized solutions tailored to your unique needs. Whether you require specific dimensions, unique graphics, or specialized functionalities, Singway can design and manufacture membrane switches that align perfectly with your specifications. This flexibility allows you to create products that stand out in the market and meet the exact demands of your customers.

4. Wide Range of Applications

Singway’s membrane switches are designed to cater to a diverse range of applications, including medical devices, automotive controls, consumer electronics, and industrial equipment. This versatility ensures that no matter your industry, Singway has the expertise and capability to provide the ideal membrane switch solution. Their extensive experience across various sectors guarantees that you receive switches that are perfectly suited to your application¨s specific requirements.

5. Excellent Customer Support

Singway prides itself on providing exceptional customer support throughout the entire manufacturing process. From initial consultation and design to production and delivery, Singway’s team of experts is dedicated to ensuring that your experience is seamless and satisfactory. Their proactive approach to customer service means that any issues or concerns are addressed promptly, ensuring that your project stays on track and within budget.

6. Cost-Effective Solutions

Despite offering top-notch quality and advanced features, Singway remains committed to providing cost-effective solutions. Their efficient manufacturing processes and economies of scale enable them to offer competitive pricing without compromising on quality. This affordability makes Singway an attractive partner for businesses looking to balance high performance with budget considerations.

7. Sustainable and Eco-Friendly Practices

Singway is dedicated to sustainable manufacturing practices and minimizing its environmental impact. They use eco-friendly materials and processes to produce membrane switches, ensuring that their products are safe for both users and the environment. By choosing Singway, you not only get high-quality switches but also contribute to a more sustainable future.

8. Innovative Design Capabilities

Innovation is at the heart of Singway’s approach to manufacturing. Their team of skilled designers and engineers continually explores new materials, technologies, and design methodologies to create membrane switches that push the boundaries of performance and aesthetics. This commitment to innovation ensures that you receive cutting-edge products that keep your offerings ahead of the competition.

9. Global Reach and Timely Delivery

With a robust global supply chain and efficient logistics, Singway ensures timely delivery of your membrane switches, no matter where you are located. Their ability to meet tight deadlines and deliver products on time is crucial for businesses that operate in fast-paced markets and rely on timely product launches and updates.