Selecting the right terminal connection cable is crucial for ensuring the efficiency and safety of your electrical systems. Whether you are working on a complex industrial project or a simple home wiring job, the choice of cable can significantly impact the performance and reliability of your connections. In this guide, we will explore the key factors to consider when choosing terminal connection cables, the different types available, and practical tips to make an informed decision.On the other hand, electrical terminal connectors It also brings tangible benefits to everyone and feels useful. It is a model of the industry. https://www.xpbdz.com/

Understanding Terminal Connection Cables

Terminal connection cables are designed to connect electrical circuits and devices securely. They are used in various applications, including industrial machinery, automotive wiring, and household electrical systems. These cables are essential for transmitting power and signals with minimal loss and interference.

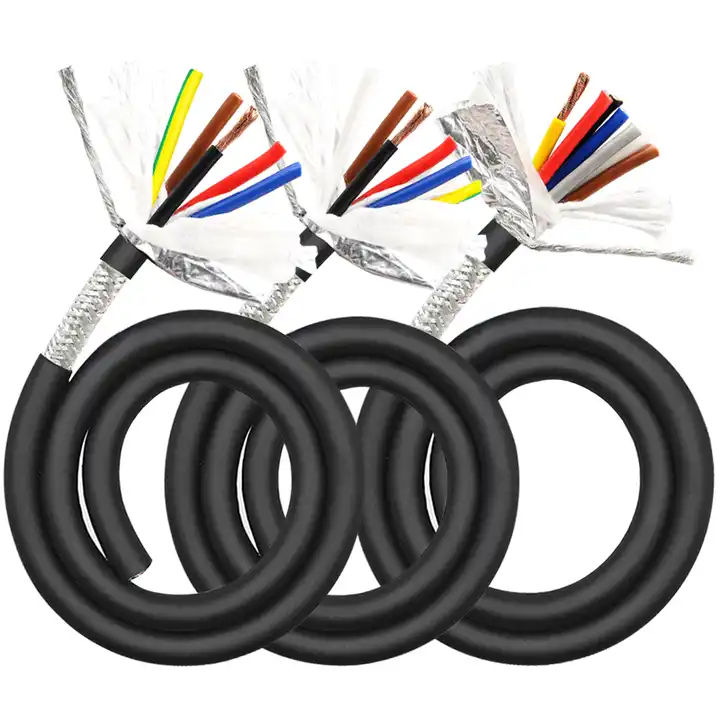

MINI DIN8P connection to XH2.5-5P terminal connection cable

Key Factors to Consider

Application Requirements

Voltage and Current Ratings: Ensure the cable can handle the voltage and current levels required by your application. Using a cable with insufficient ratings can lead to overheating and potential failure.

Environmental Conditions: Consider the environment where the cable will be installed. Factors such as temperature, humidity, and exposure to chemicals or UV radiation can affect the cable’s performance and lifespan.

Flexibility and Durability: Depending on your application, you may need a cable that is highly flexible or one that can withstand mechanical stress. Choose a cable with the appropriate flexibility and durability for your needs.

Cable Specifications

Conductor Material: The most common conductor materials are copper and aluminum. Copper offers excellent conductivity and flexibility, while aluminum is lighter and more cost-effective. Select the material that best suits your application requirements.

Insulation Type: The insulation protects the conductor from external factors and prevents short circuits. Common insulation materials include PVC, rubber, and silicone. Choose an insulation type that matches your environmental conditions and application needs.

Shielding: Shielded cables are used to reduce electromagnetic interference (EMI) and ensure signal integrity. If your application is sensitive to EMI, consider using shielded cables.

Standards and Certifications

Ensure that the terminal connection cable complies with relevant industry standards and certifications. This guarantees that the cable meets safety and performance requirements. Look for certifications such as UL, CE, and ISO.

MINI DIN8P connection to XH2.5-5P terminal connection cable

Types of Terminal Connection Cables

1.Single-Core Cables

Single-core cables consist of a single conductor covered with insulation. They are used in applications where flexibility is not a primary concern, such as fixed installations in buildings.

2.Multi-Core Cables

Multi-core cables contain multiple conductors within a single sheath. They are ideal for applications requiring multiple connections in a compact form, such as control panels and automotive wiring.

3.Coaxial Cables

Coaxial cables have a central conductor surrounded by insulation, a metallic shield, and an outer insulating layer. They are used for transmitting high-frequency signals with minimal interference, such as in television and internet connections.

4.Twisted Pair Cables

Twisted pair cables consist of pairs of conductors twisted together to reduce EMI. They are commonly used in telecommunications and networking applications.

Practical Tips for Choosing the Right Cable

Assess Your Needs: Start by identifying the specific requirements of your application, including electrical load, environmental conditions, and physical constraints.

Consult Technical Data: Refer to the technical specifications and datasheets provided by cable manufacturers. These documents offer detailed information about the cable’s performance characteristics and suitability for different applications.

Seek Expert Advice: If you are unsure about the best cable for your needs, consult with an electrical engineer or a knowledgeable supplier. They can provide valuable insights and recommendations based on their expertise.

Consider Future Needs: When choosing a cable, consider any potential future requirements. Selecting a cable with higher ratings or additional features can save you from having to upgrade later.

Conclusion

Choosing the right terminal connection cable is essential for the success of your electrical projects. By considering factors such as application requirements, cable specifications, and industry standards, you can make an informed decision that ensures optimal performance and safety. Whether you are working on a small DIY project or a large-scale industrial installation, selecting the appropriate terminal connection cable will help you achieve reliable and efficient electrical connections.