A USB hub laptop stand is a multifunctional solution that combines the practicality of a USB hub with the ergonomic benefits of a laptop stand. Designed to meet the needs of modern professionals, students, and gamers, it simplifies desktop wiring and improves both heat dissipation and posture. Whether you¨re working, studying, or gaming, this versatile tool has become a must-have for a seamless and efficient workspace.Through bit by bit efforts, let Professional USB Hub Producer Our market share is getting higher and higher, and the return on investment is also rising steadily. https://worldtypec.com/

Why USB Hub Laptop Stand is the Perfect Tech Accessory.jpg1. What is a USB Hub Laptop Stand?

A USB hub laptop stand merges two essential features into one:

USB Hub Functionality: Allows users to connect multiple devices like external monitors, keyboards, or mobile phones to their laptop.

Laptop Stand Design: Elevates the screen for better ergonomics, reducing neck and back strain while enhancing heat dissipation.

This dual functionality makes it popular for work-from-home setups, creative projects, and gaming enthusiasts.

2. Why Do You Need a USB Hub Laptop Stand?

2.1 Limited Interfaces on Modern Laptops

Ultra-thin laptops, such as MacBook or Dell XPS models, often have limited ports. A USB hub laptop stand meets the demand for more connections by integrating ports like USB-C, HDMI, and SD card readers.

2.2 Improved Ergonomics for Work and Gaming

By elevating the laptop screen to eye level, a USB hub laptop stand helps reduce cervical fatigue and improve posture. This ergonomic design enhances comfort during long work sessions or gaming marathons.

2.3 Multi-Device Connectivity

For users juggling multiple devices, a USB hub laptop stand offers seamless connections to peripherals like external drives, mice, keyboards, and even smartphones. This eliminates the need for additional adapters or hubs, keeping your workspace organized.

3. Core Functions of a USB Hub Laptop Stand

3.1 Multi-Port Design

A typical USB hub laptop stand includes multiple ports, such as:

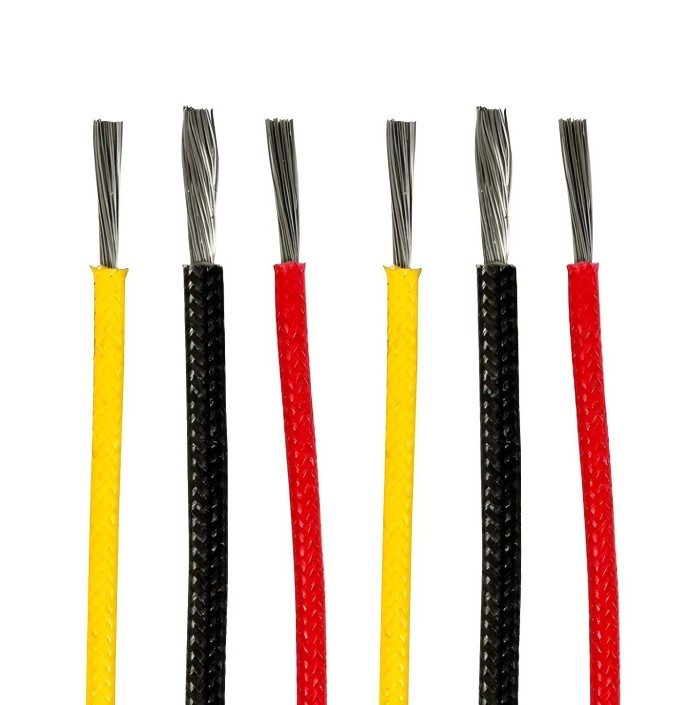

USB-A: For traditional USB devices.

USB-C: For fast charging and high-speed data transfer.

HDMI: For external monitors or projectors.

SD/TF Card Slots: For creators and photographers.

3.2 Fast Charging and Data Transfer

The USB-C interface supports fast charging (up to 60W) and high-speed data transfer rates (up to 10Gbps), saving both time and desk space.

3.3 Adjustable Height and Angle

Adjustable designs ensure that the USB hub laptop stand meets different ergonomic needs, making it ideal for various working or viewing positions.

3.4 Heat Dissipation

Many USB hub laptop stands feature open designs or built-in fans to improve airflow, preventing laptops from overheating during extended use.

USB Hub Laptop Stand with product display.jpg4. Who is the USB Hub Laptop Stand Suitable For?

4.1 Remote Workers

A USB hub laptop stand helps integrate devices like external monitors and keyboards, improving productivity in home offices.

4.2 Students and Creators

With multiple ports for connecting tablets, flash drives, or cameras, this device is perfect for students and digital creators managing multiple gadgets.

4.3 Gamers

Gamers benefit from improved laptop cooling and the ability to connect external gaming peripherals like headphones, mice, and keyboards.

4.4 Business Travelers

Portable and lightweight, a USB hub laptop stand is a great travel companion, offering both connectivity and ergonomic benefits on the go.

5. How to Choose the Right USB Hub Laptop Stand

5.1 Port Configuration

Consider the types and number of ports required, such as HDMI for external displays or USB-C for fast charging.

5.2 Material and Stability

Choose durable materials like aluminum alloy for stability and long-lasting use.

5.3 Heat Dissipation Design

Look for stands with ventilation grids or built-in fans for better cooling.

5.4 Adjustability

Ensure the stand supports adjustable heights and angles for personalized ergonomics.

5.5 Budget-Friendly Options

Choose cost-effective brands that balance features with price, like those offered by WorldPass.